Conversion chains / Fault tolerance / Control

Marine Renewable Energy (MRE) applications

DSPMG low speed machine test bench

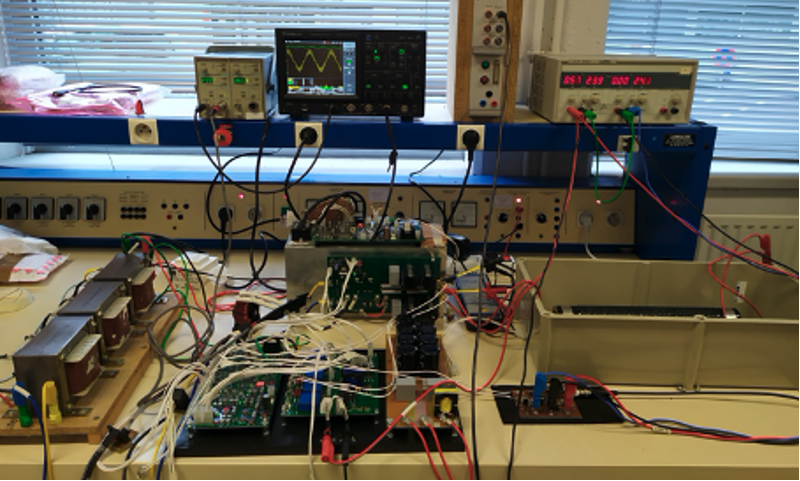

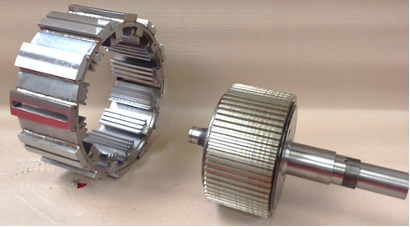

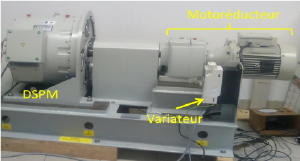

This test bench, developed within the framework of the interregional Hydrol 44 project piloted by the laboratory, implements a low-speed dental-coupled machine excited at the stator by permanent magnets, mainly for tidal turbine applications. It enables the operating principle to be validated and the ad hoc control algorithms to be implemented.

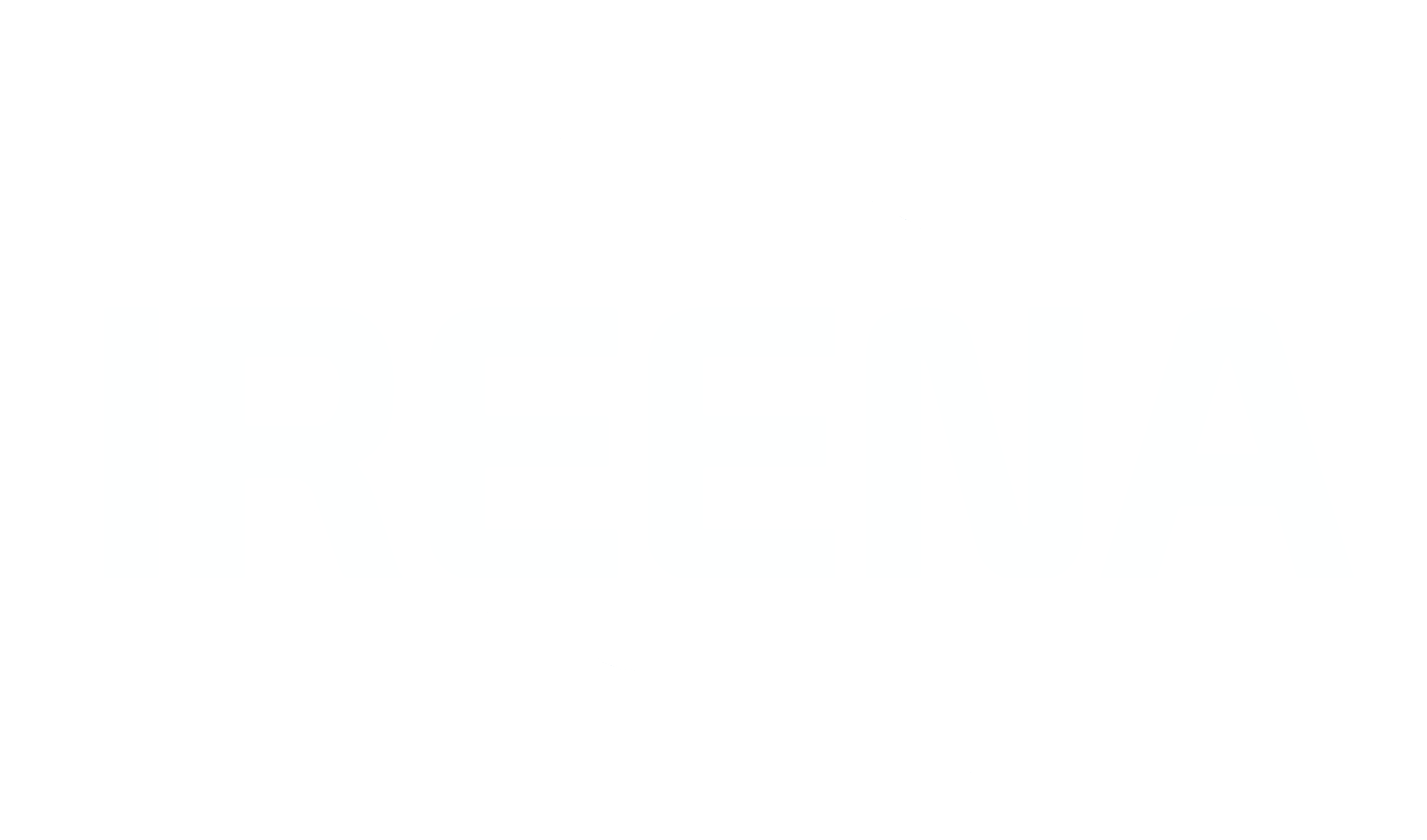

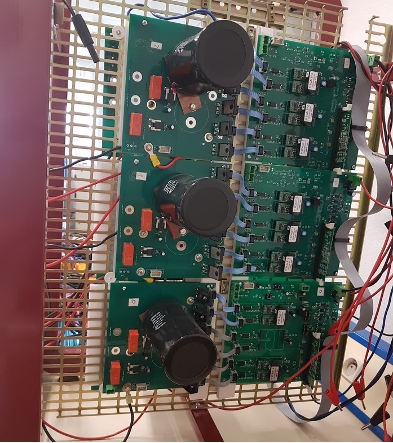

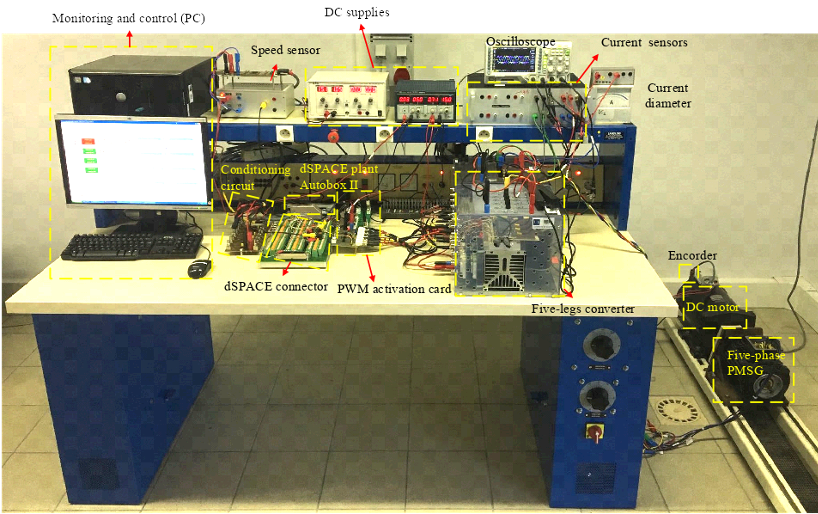

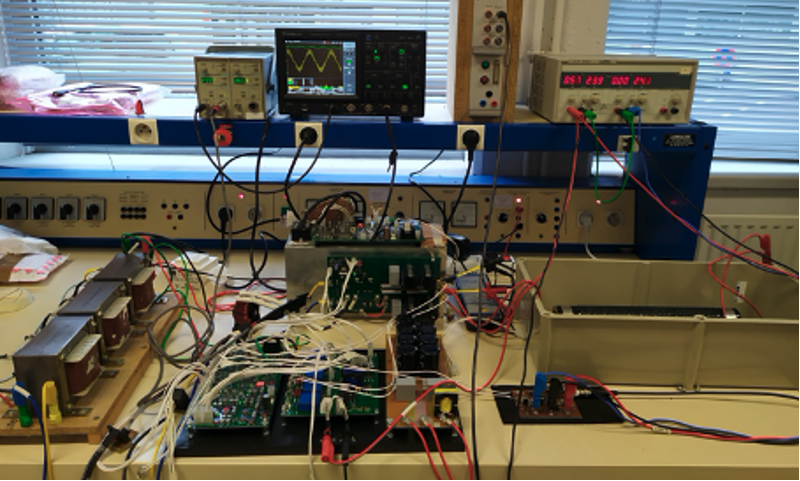

This 3 kW test bench consists of a 5-phase permanent magnet machine coupled to a DC machine. This test bench is used to evaluate the benefits of using multi-phase machines for various demanding applications such as MRE (wind, tidal) and transport. This consists of exploiting redundant phases to ensure continuity of service following a fault. Currently, work is being carried out on the fault tolerance of this conversion chain. The objective is to detect, locate and reconfigure control strategies in the event of typical faults (open or short-circuited switches, open phase, etc.).

5-phase machine, its converter and its control interface.

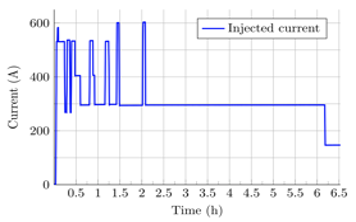

This experimental bench is used to test the electro-thermal response of a 20kV export cable as installed on the SEM-REV (ECN) sea trial site. This cable, a key element in the architecture of MRE systems and their connection to the grid, is often expensive and complex to dimension. Based on a multi-physics approach, this bench allows the validation/calibration of COMSOL models. An electrothermal coupling, a wide bandwidth power emulator allows the generation of full-scale current profiles (up to 600 Arms).

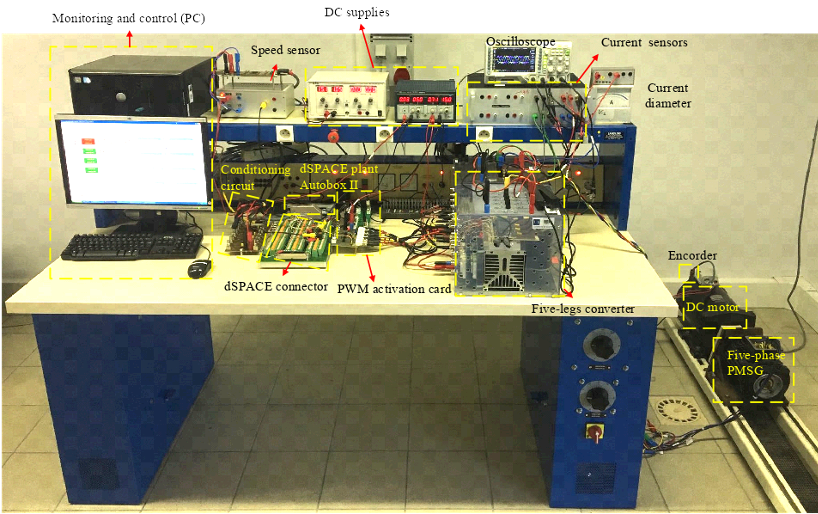

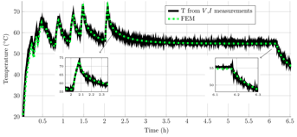

A test bench (30,000 rpm, 20 kW) designed on the basis of modeling and optimisation work carried out by the IREENA laboratory was built. The two identical machines are surface-mounted permanent magnet synchronous machines with carbon fibre banding. The tests carried out validate the dimensioning models on which our optimisation approaches are based, particularly the optimisation of machines working on cycles.

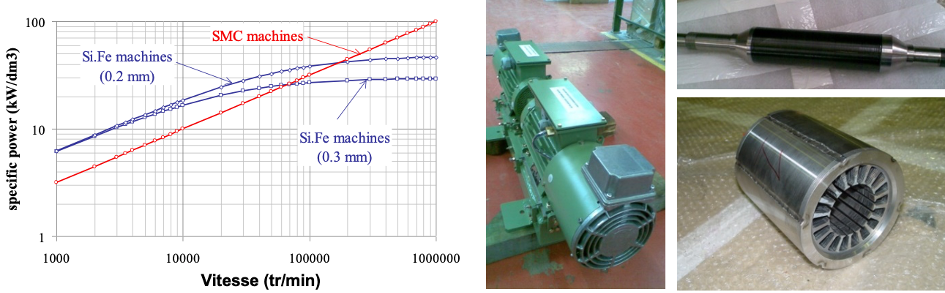

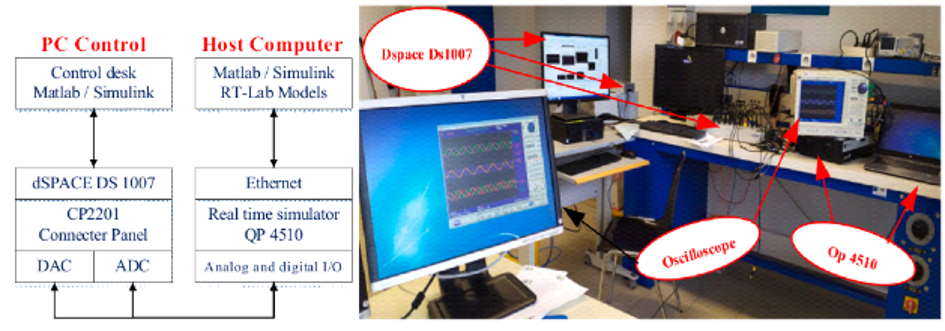

This bench consists of an Opal-RT 4510 system coupled to a Dspace-1007 system. In this configuration, the control laws implemented in Dspace allow the power system implemented in the Opal RT target to be driven. In parallel with the existing benches in the laboratory, this bench allows, among other things, the scaling up of the systems studied.

HIL Opal-RT and DSpace test bench for tuning and validation of control algorithms.

The test bench allows the control with sinusoidal absorption of a single-phase or three-phase AC/DC Vienna converter. The digital board, allowing the control by digital MRC, is built around a Cyclone 10LP FPGA with an operating frequency of 50MHz. The surrounding architecture allows for 12- and/or 16-bit analogue-to-digital conversion. Synchronisation on the network is achieved in an analogue way via a PLL based on an MC14046BCP. A DC/DC converter can be coupled downstream of the AC/DC converter to reproduce the complete architecture of an electric arc welder. The maximum power ratings allowed by the Vienna converter design are approximately 6kW single phase and 18kW three phase.

Vienna rectifier PFC test bench

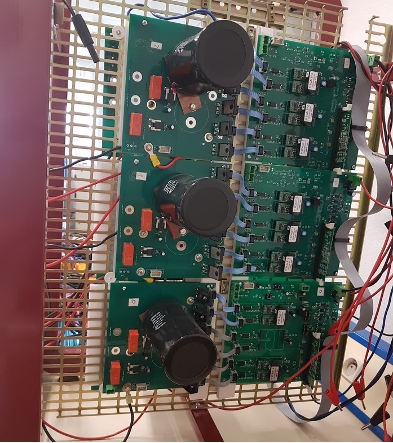

A 6-module MMC converter prototype has been developed in the laboratory with the aim of validating energy management and control laws for these new structures, in particular for the integration of distributed storage devices into HVDC networks. Currently, a new prototype is being developed, based on SiC components and integrating new intelligent driver technologies (work developed in partnership with the IETR). This time, it should make it possible to test and validate chained communication algorithms, making it possible to limit the amount of information exchanged between the modules.

MMC converter prototype designed and built in the IREENA laboratory.

|

|

| Exploded view of the DSPMG generator | B Low-speed machine control bench with DSPMG generator with its drive motor |

5-phases machine bench / Fault tolerance

This 3 kW test bench consists of a 5-phase permanent magnet machine coupled to a DC machine. This test bench is used to evaluate the benefits of using multi-phase machines for various demanding applications such as MRE (wind, tidal) and transport. This consists of exploiting redundant phases to ensure continuity of service following a fault. Currently, work is being carried out on the fault tolerance of this conversion chain. The objective is to detect, locate and reconfigure control strategies in the event of typical faults (open or short-circuited switches, open phase, etc.).

5-phase machine, its converter and its control interface.

Electrothermal characterisation bench for cables

This experimental bench is used to test the electro-thermal response of a 20kV export cable as installed on the SEM-REV (ECN) sea trial site. This cable, a key element in the architecture of MRE systems and their connection to the grid, is often expensive and complex to dimension. Based on a multi-physics approach, this bench allows the validation/calibration of COMSOL models. An electrothermal coupling, a wide bandwidth power emulator allows the generation of full-scale current profiles (up to 600 Arms).

|

|

| Experimental characterisation bench, integrating the cable under test and the network emulator |

Measurement results and model calibration |

Special machines

30 000 rpm – 20 kW test bench : High-speed machines rapides with high power density

A test bench (30,000 rpm, 20 kW) designed on the basis of modeling and optimisation work carried out by the IREENA laboratory was built. The two identical machines are surface-mounted permanent magnet synchronous machines with carbon fibre banding. The tests carried out validate the dimensioning models on which our optimisation approaches are based, particularly the optimisation of machines working on cycles.

| Evolution of the optimal power density for different speeds and different materials | Test bench with permanent magnet synchronous machines (30,000 rpm - 20 kW) |

Control and diagnostics

Hardware In the Loop (HIL) simulation bench

This bench consists of an Opal-RT 4510 system coupled to a Dspace-1007 system. In this configuration, the control laws implemented in Dspace allow the power system implemented in the Opal RT target to be driven. In parallel with the existing benches in the laboratory, this bench allows, among other things, the scaling up of the systems studied.

HIL Opal-RT and DSpace test bench for tuning and validation of control algorithms.

Power electronics

Dedicated test bench for the sine wave absorption regulation of a Vienna converter by digital MRC

The test bench allows the control with sinusoidal absorption of a single-phase or three-phase AC/DC Vienna converter. The digital board, allowing the control by digital MRC, is built around a Cyclone 10LP FPGA with an operating frequency of 50MHz. The surrounding architecture allows for 12- and/or 16-bit analogue-to-digital conversion. Synchronisation on the network is achieved in an analogue way via a PLL based on an MC14046BCP. A DC/DC converter can be coupled downstream of the AC/DC converter to reproduce the complete architecture of an electric arc welder. The maximum power ratings allowed by the Vienna converter design are approximately 6kW single phase and 18kW three phase.

Vienna rectifier PFC test bench

MMC converter prototype

A 6-module MMC converter prototype has been developed in the laboratory with the aim of validating energy management and control laws for these new structures, in particular for the integration of distributed storage devices into HVDC networks. Currently, a new prototype is being developed, based on SiC components and integrating new intelligent driver technologies (work developed in partnership with the IETR). This time, it should make it possible to test and validate chained communication algorithms, making it possible to limit the amount of information exchanged between the modules.

MMC converter prototype designed and built in the IREENA laboratory.

IREENA's equipment and platforms have been partly co-financed by the European Regional Development Fund (ERDF).

Cofunding

IREENA's equipment and platforms were partly co-financed by the European Regional Development Fund (ERDF).

Unit Director

Head of TRU 1

Head of TRU 2

Head of TRU 3

Updated on 19 November 2024.